The main advantage of 3D printing is its flexibility and functionality for small scale manufacturing and rapid prototyping. We are able to provide high quality 3D prototype production part fabrication quickly on demand, offering the latest 3D printing service technologies such as FDM, SLA, SLS, MJF, etc. to provide the most suitable solution for your 3D order. We offer six 3D printing technologies to create affordable parts for you in metal/plastic and more.

FDM is widely known for its high speed, high accuracy and low cost 3D technology. We offer a wide range of colours, FDM part finishing and FDM materials for you to choose from.

SLA is ideal for producing parts with extremely high accuracy and resolution, injection moulding effects, surface smoothness and feature detail. It is a highly versatile platform for part prototyping and production set-up.

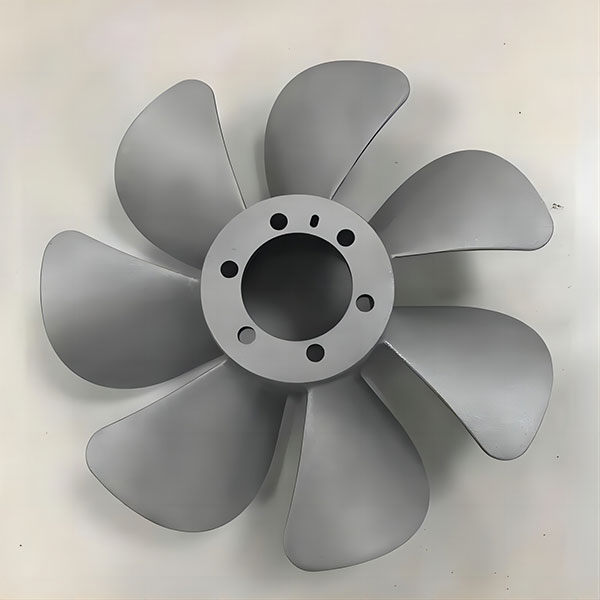

SLS is used to produce functional plastic parts with good mechanical properties and high precision. All of these parts can be used for end use, low volume production and rapid prototyping.

MJF starts by depositing a thin layer of powdered material onto a platform, then the molten droplets are mixed with a refining agent and heat is applied to the top of the material to define the geometry of the part.

The DMLS printing process can produce highly complex features and integrally assembled metal parts that are difficult to achieve with subtractive manufacturing techniques.

Binder Jetting has multiple capabilities in diverse production of functional metal parts, full-color prototypes, figurines, and large sand casting. The powder materials commonly used in Binder Jetting process are metal and ceramics.

Conceptual models: The speed and versatility of custom 3D printing projects allows product developers to create physical snapshots of their designs through an iterative process.

Rapid Prototyping: 3D printing can be used to create fully functional prototypes, including moving parts and all-in-one components.

Direct Digital Manufacturing: The high accuracy and consistency of 3D printing makes it an ideal way to build production volumes of discrete or customised parts.

|

Part Size |

Can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

|

Minimum Feature Size |

0.030" - 0.060" is typical |

|

Minimum Wall Thickness |

0.020" - 0.060" is typical |

|

Clearance Between Features |

At least 0.030" |