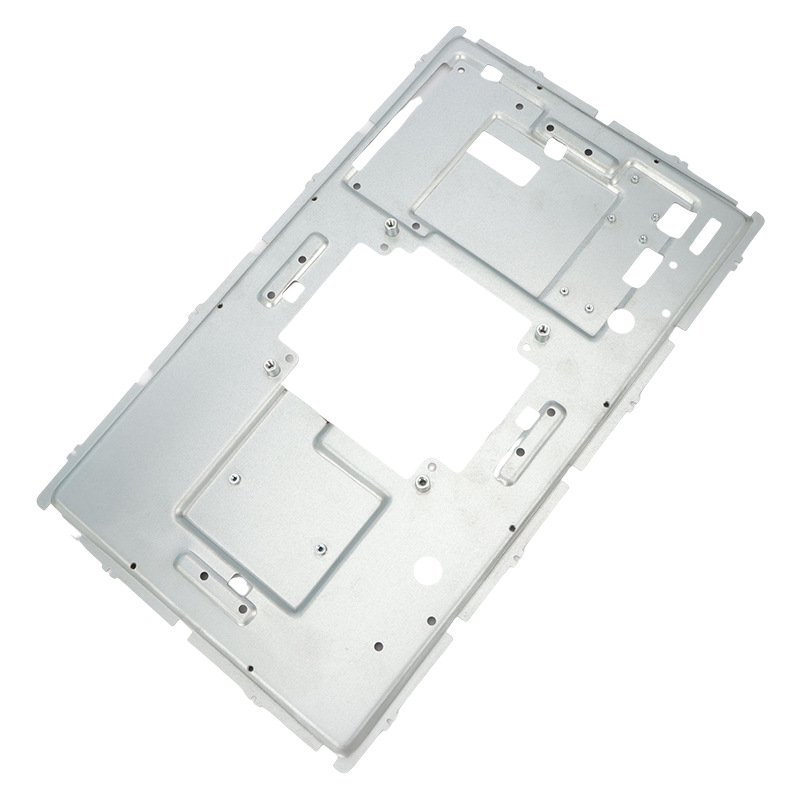

Sheet metal forming is a process that uses machine-controlled equipment to accurately bend, punch and cut metal to produce sheet metal parts for rapid prototyping and low-volume production. Known for their high precision and durability, sheet metal parts are ideal for end-use applications such as chassis, enclosures and brackets.

Cutting thin sheet metal with a high-density beam where a CNC can be used to control the laser beam or the workpiece. Intense lasers can cut sheet metal from 0.5 mm to 10 mm thick to produce prototypes for a large number of parts.

It uses a mould to generate V-, U- or slot shapes in ductile materials along a straight axis. It is suitable for forming stainless steel, steel and aluminium parts, as well as for rapid prototyping of custom sheet metal after the cutting process.

• Bead Blast

• Anodize (Type II Or Type III)

• Chem Film (Chromate Conversion Coating)

• Powder Coat

• Aluminium 6061

• Aluminium 5052

Aluminium is one of the common materials used for sheet metal fabrication.

• Stainless Steel 301

• Stainless Steel 304

• Stainless Steel 316/316L

Stainless steel has excellent weldability, formability and corrosion resistance, making it ideal for sheet metal fabrication.

• Copper 101

• Copper C110

• Copper 260 (Brass)

With high formability, strength, corrosion resistance and electrical conductivity, brass is also an excellent choice for sheet metal fabrication.

• Steel, Low Carbon

• Sheet metal parts are parts with high durability, ductility and pressure resistance for functional prototyping and final production.

• You can choose from a wide range of sheet metal types in terms of strength, conductivity, weight and corrosion resistance.

• Customised finishes are varied and include anodising, plating, powder coating and painting.

• Low investment in tooling and preparation costs for sheet metal parts such as brackets and chassis.

• Cost-effective scaling to low or high production volumes.

Sheet metal fabrication is a versatile manufacturing method for a variety of metal products across a wide range of industries. This process is cost-effective for low-volume, high-mix prototypes, and high-volume production runs. Part of common sheet metal parts are as follows:

• Appliances

• Electrical enclosure

• Body panels

• Brackets

• Parts for computer electronics

• Chassis

• Mounts

• Enclosures

• Cabinets

• Fuselages

• Kitchen equipment

• Office equipment