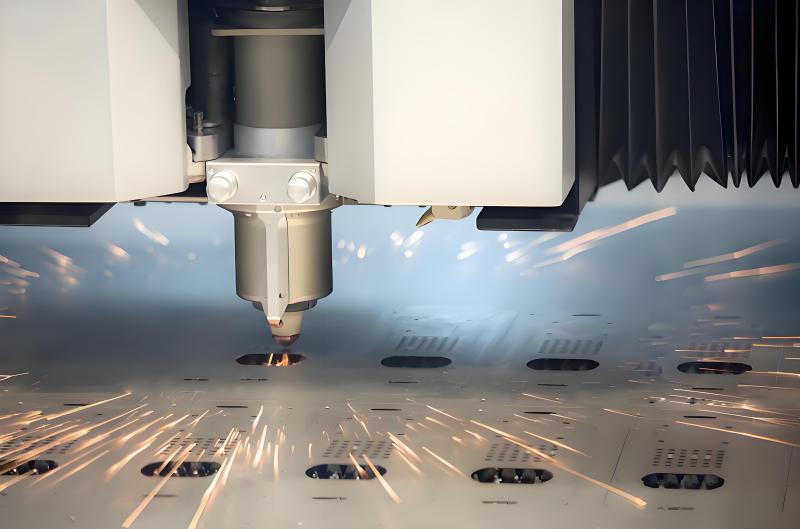

Laser cutting machines convert laser energy into extremely intense heat by focusing the laser beam. This heat is enough to melt or vaporise metal, and laser cutting produces consistently clean edges to the tightest tolerances. It has a faster turnaround time than punching, saves time on short runs and is more accurate and consistent than mechanical cutting. Laser cutting is a flexible, versatile manufacturing solution for parts with complex geometries that require distortion-free finishes.

• Fast cutting speed, stable cutting speed, can achieve rapid cutting, flash cutting and other cutting methods.

• It can effectively cut metal sheets of various materials, such as carbon steel, stainless steel, aluminium, alloy and non-ferrous metals.

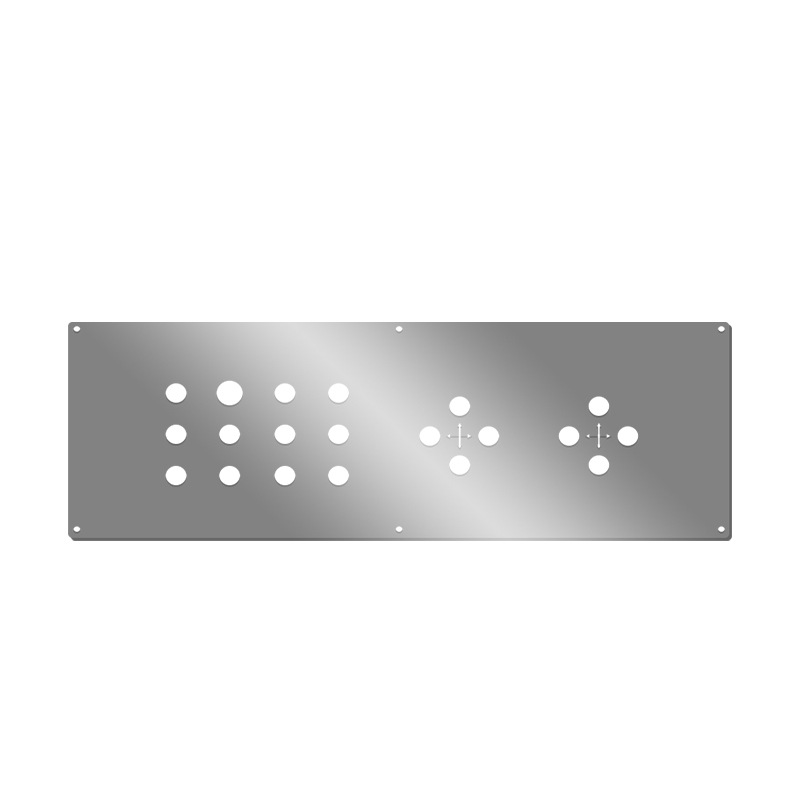

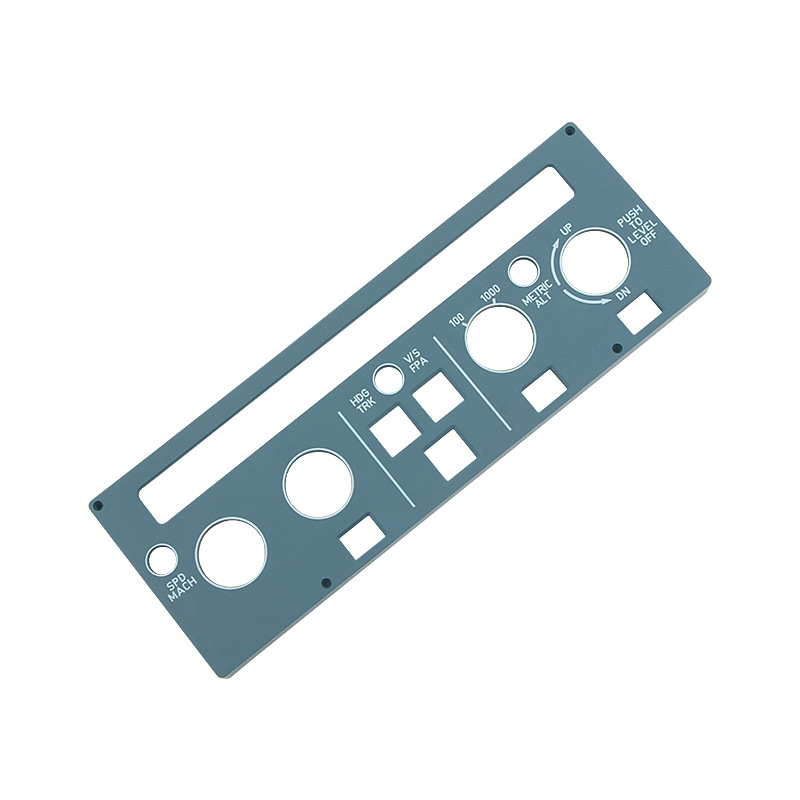

• The sheet metal cut by laser cutting machine has little influence of hot zone, smooth section and narrow kerf. The roughness of the cut section is as low as tens of microns, without secondary processing, all shaped.

• Laser cutting dimensional accuracy is high, can cut obtuse corners and narrow seams.